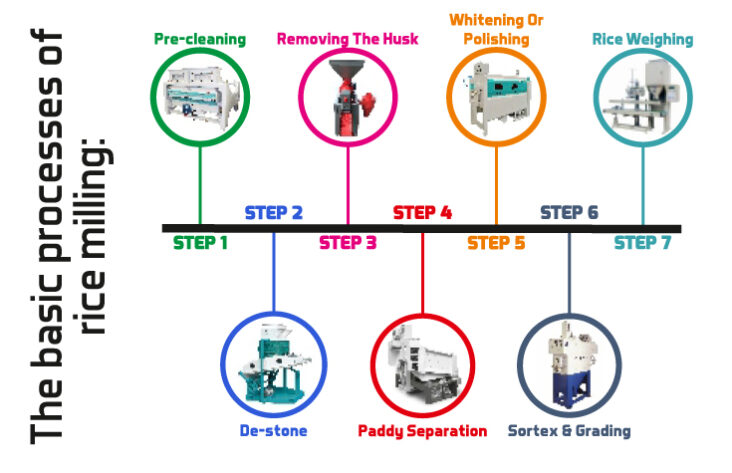

The Basic Processes of Rice Milling

The process of rice milling often assists in removing the hills and brans from the paddy grains. As a result, we can get the polished rice. Further milling process provides the white rice which is done by machines and it rubs the grains together under certain pressure.

The basic processes of rice milling are:

Step 1: Pre-cleaning

Generally, paddy contains several foreign materials like straw, soil, weed seeds etc when it comes into the mill. These all must be removed before hulling. If these are left unremoved, the efficiency of the huller and milling recovery will be reduced.

Step 2: De-stone

This process involves removing the small stones from the paddy.

Step 3: Removing the husk

Brown rice is produced by removing husks from coarse rice. The husk is moved by friction as the sheaf of rice passes between two abrasive surfaces which move at distinct speeds. After the process of dehusking, the husk is removed by suction method. And therefore it is transported to a storage dump outside the mill.

Step 4: Paddy separation

The unhusked paddy rice from brown rice is separated by the paddy separator. Paddy separators operate by using the differences in certain gravity, buoyancy, as well as the size between paddy and brown rice.

Step 5: Whitening or polishing

White paddy is produced by removing the husk layer and germs from the paddy. The bran layer is removed from the kernel by an abrasive polisher.

Step 6: Sortex & Grading

Mixing fine water mist with the dust held on the whitened rice improves the brightness (polish) of the rice without even reducing the milling yield.

Step 7: Rice weighing In general, rice is sold in 50 kg bags, so that it must be weighed and labeled properly. Although the majority of the rice mills employ a method of manual mechanical weighing which is very accurate. Fast electronic systems are also available.